PT Michelin Indonesia

PT Michelin Indonesia adalah perusahaan yang bergerak di bidang manufaktur ban, merupakan bagian dari Michelin Group yang berpusat di Prancis. Perusahaan ini memproduksi berbagai jenis ban, termasuk ban untuk kendaraan roda dua dan roda empat, serta memiliki pabrik di Cikarang Timur, Jawa Barat. Dahulu, PT Michelin Indonesia dikenal sebagai PT Multistrada Arah Sarana Tbk (MASA) sebelum diakuisisi oleh Michelin. Lowongan Kerja PT Michelin Indonesia.

Lowongan Kerja PT Michelin Indonesia

Saat ini PT Michelin Indonesia sedang membuka lowongan kerja dengan posisi sebagai berikut:

1. Mechanical Engineer Intern

About the Role :

- As a Mechanical Engineer Intern at Michelin, you will gain hands-on experience in improving production efficiency, reliability, and safety within a world-class manufacturing environment. Guidance will be provided by experienced engineers as you contribute to the design, improvement, and implementation of mechanical systems that support our tire production process

What You’ll Do :

- Assist in designing and improving mechanical components, tools, and equipment.

- Participate in production line improvement projects.

- Analyze equipment performance data to recommend solutions.

- Prepare technical documentation and project reports.

What We’re Looking For :

- Active and final-year student in Mechanical Engineering or related field.

- Available for a min. 6-months internship program.

- Good communication skills in both written and spoken English.

- Strong interest in mechanical design and manufacturing processes.

- Able to read and interpret technical drawings.

- Basic understanding of pneumatic, hydraulic, and drive systems.

- Good analytical and problem-solving skills.

- Willing to be based in Cikarang, West Java.

2. Automation Engineer Intern

KEY EXPECTED ACHIEVEMENTS:

- Support the implementation and optimization of automated systems

- Work on automation projects to improve productivity and safety

- Support the implementation and optimization of automated systems

- Analyse process data and propose automation-based solutions

- Prepare technical documentation and support testing activities.

WHAT WE’RE LOOKING FOR:

- Active and final-year student in Electrical Engineering, Mechatronics Engineering, Automation Engineering, or related field.

- Available for a min. 6 months internship program.

- Good communication skills in both written and spoken English.

- Passion for industrial automation and process control.

- Basic knowledge of programming, sensors, and control systems.

- Familiarity with industrial robotics is a plus.

- Good problem-solving skills and attention to detail.

- Willing to be based in Cikarang, West Java.

WHY JOIN US:

- Work directly with advanced automation technology

- Gain hands-on industrial automation experience.

- Learn from experts in a leading global manufacturing company.

3. Management Production

Key Responsibilities:

- People Leader & Developer

- Build a strong, inclusive, and skilled team from frontline to leadership

- Mentor, coach, and provide clear career paths and learning opportunities

- Promote a culture of safety, trust, and continuous improvement

- Shop Performance Driver

- Lead the day-to-day production operations to meet safety, quality, delivery, cost & sustainability (SMQDC) goals

- Conduct regular performance reviews and foster autonomy and responsibility in teams

- Identify and eliminate inefficiencies using lean tools and problem-solving methods

- Strategy Champion & Company Role Model

- Embody and promote company values, vision, and sustainability mission

- Drive collaboration across teams and support plant-level strategic decisions

- Represent the plant to your team and ensure alignment with plant objectives

- Customer & Business Partner

- Understand customer expectations and ensure your Shop delivers value

- Work cross-functionally to support industrialization, innovation, and transformation projects

- Innovation & Digital Contributor

- Lead digital transformation initiatives within the Shop

- Encourage experimentation and leverage technology to unlock efficiency

- Support plant roadmap and collaborate with technical and digital teams

What We’re Looking For:

- Bachelor’s or Master’s degree in Engineering or a related technical discipline.

- 3–5 years of experience in a manufacturing or production environment.

- Explain how their daily responsibilities in past roles reflected a personal commitment to health and safety, going beyond compliance to actively promote a safety-first culture.

- Describe how their department contributed to improving overall performance and how they used the Production System to bring value across all domains including safety, quality, delivery, cost, people, and environment.

- Provide clear examples of how they: Facilitated teamwork and cross-functional coordination, Promoted inclusivity and built trust within diverse teams, Recognized team contributions and supported adaptability during change, Encouraged flexibility and continuous learning, Managed adjustments and inspired innovation to solve challenges.

- Share past experiences where they applied structured problem-solving approaches to identify root causes and implement long-term solutions.

- Demonstrate a solid understanding of capacity structure, production flow, and operational commitments, with the ability to manage and optimize resources effectively.

- Minimum English proficiency of B2 level.

- Willingness to be placed in Cikarang.

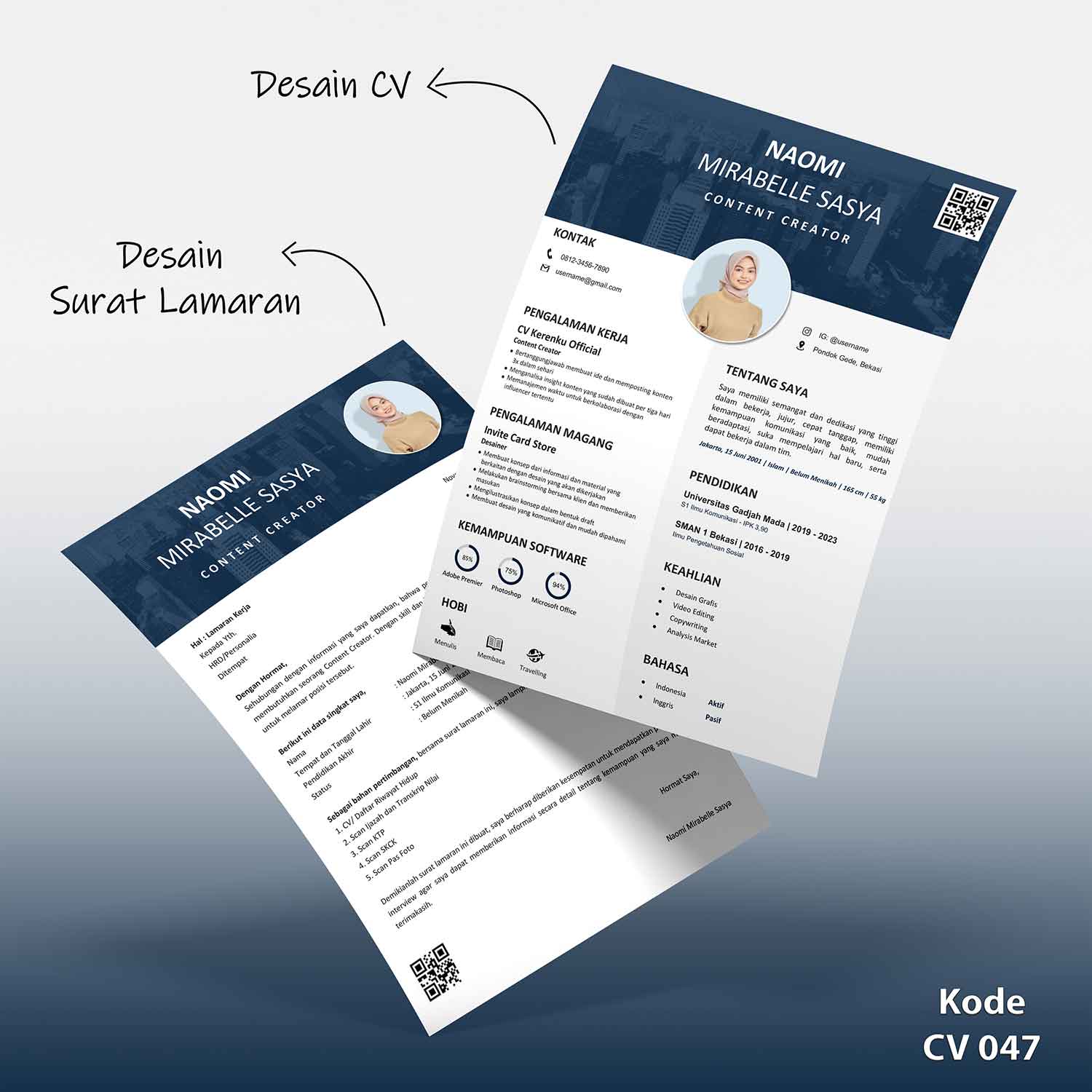

Solusi CV Terbaik untuk lamar Kerja?

@cv.kerenku aja!

Sudah membantu lebih dari 50.000 pelamar kerja

Tata Cara Melamar

Bagi yang berminat dan memenuhi kualifikasi yang dibutuhkan, silakan apply melalui link berikut:

|

1. Mechanical Engineer Intern |

DAFTAR |

|

2. Automation Engineer Intern |

DAFTAR |

|

3. Management Production |

DAFTAR |

Hanya kandidat yang sesuai dengan kualifikasi yang akan mengikuti proses selanjutnya

Hati-hati terhadap segala bentuk jenis penipuan karena sejatinya pendaftaran lowongan kerja gratis tidak ada biaya dalam bentuk apapun